Bruce Power’s Life-Extension Program and Major Component Replacement (MCR) Project continues to progress safely and on schedule as the company refurbishes Units 3-8 in one of Canada’s largest clean energy infrastructure projects.

Recently, the Unit 4 MCR progressed to its removal and replacement series following a strong lead-in after the unit was taken off-line in February to begin its three-year refurbishment. The removal and replacement of major CANDU reactor components includes 480 fuel channels, 960 feeder tubes, eight steam generators, and many other upgrades that will allow Bruce Power to return Unit 4 to service with new reactor components to supply clean energy to the province as demand rises in the decades to come.

Bruce Power’s multi-year Life-Extension Program, scheduled to be completed in 2033, represents the largest private-sector investment in Canada’s nuclear industry and generation infrastructure. Strong performance in the Unit 4 outage lead-in was built on the success of the first completed MCR in Unit 6 and the innovations and performance improvements for Unit 3, which remains on plan to return to service in 2026.

“Along with our partners and skilled tradespeople, we’re seeing excellent performance as we complete each MCR outage safely, on plan, and to a high-quality standard,” said Eric Chassard, Bruce Power’s president and Chief Executive Officer. “Together, we’re working to return these units to service safely and successfully to meet Ontario’s clean energy needs and provide cancer-fighting medical isotopes for patients around the world for decades to come.”

Success stories during the Unit 4 lead-in included the safe and ahead-of-schedule installation of 16 eight-tonne bulkheads, and the fastest defuel in the history of CANDU units.

The Bruce Power Refurbishment is No. 3 on ReNew Canada’s 2025 Top100 Projects report.

Shoreline, a joint venture between Aecon and Candu Energy, an AtkinsRéalis company, will begin the Fuel Channel Feeder Replacement (FCFR) program, which sees the removal and replacement of pressure tubes, calandria tubes, and feeders inside the reactor. Skilled tradespeople are using innovative robotic tooling from ATS Automation to improve performance and safety in each successive MCR outage.

“Shoreline and our skilled tradespeople are proud to partner with Bruce Power to deliver these refurbishment outages safely, on time and with quality performance to help power Ontario well into the future,” said Jean-Louis Servranckx, president and CEO of Aecon, on behalf of Shoreline Power Group. “We’re leveraging experience and innovation as our highly trained tradespeople and multidisciplinary teams continue to drive our successful project execution.”

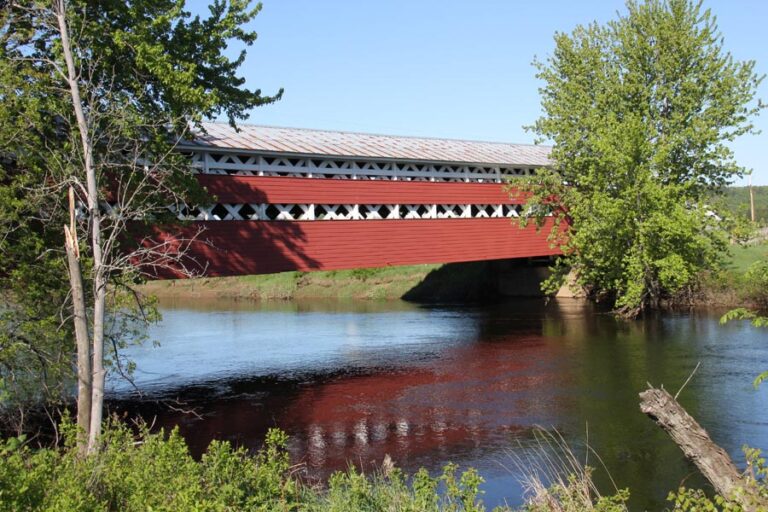

Featured image: (Bruce Power)