In support of its target to achieve a 30 per cent reduction in direct CO2 emissions by 2030 and reach net-zero by 2050, Aecon recently became the first construction company in Ontario to pilot a new low carbon concrete from Carbon Upcycling Technologies at its Innovation and Training Centre.

“We made significant progress toward achieving our ambitious GHG emissions targets in 2021 – achieving a 15 per cent reduction across our operations – and this pilot further underscores the momentum of our sustainability program as we lead the industry in pursuing the most innovative methods and technologies associated with sustainable construction,” said Jean-Louis Servranckx, president and CEO, Aecon.

Carbon Upcycling enables the production of low carbon concrete by creating CO2-embedded cement and concrete additives, also known as a Supplementary Cementitious Material (SCM). During the upcycling process, CO2 is permanently captured into the SCM, and when used in concrete, the CO2-embedded SCMs reduce the embodied emissions by up to 30 per cent while exceeding strength activity performance by up to 40 per cent.

“Concrete is among the most widely used construction materials and completing this trial is an important progression in evaluating our low carbon alternatives to reduce embodied carbon and transition to a net-zero economy,” said Yonni Fushman, chief sustainability officer and chief legal officer, Aecon. “Our team was impressed to see greater durability in comparison to other SCM options.”

As announced with the release of its third annual Sustainability Report entitled Building Innovation, Aecon proudly became the first construction company in Canada to complete a scan of indirect (Scope 3) emissions. Indirect Scope 3 emissions include those arising from supply chains and the embodied carbon in building materials, such as concrete.

During the pilot, the concrete was produced and poured by Dufferin Concrete, with CRH Slag cement from Ash Grove, which was treated with the Carbon Upcycling Technology (CUT) process. Both Dufferin Concrete and Ash Grove are CRH companies in Canada.

“We are proud to participate in this important initiative that demonstrates our ability as partners in the construction industry to find common solutions to contribute to a net-zero economy,” said Robert Bourbeau, president, CRH Canada, Construction & Materials.

The pilot was conducted at Aecon’s Innovation and Training Centre in Holland Landing, Ontario, which enables teams to trail the latest technology and process improvements before implementing across its operations.

“It’s inspiring to see how quickly teams across Aecon have embraced sustainable construction opportunities, resulting in several promising pilots of innovative methods and technologies,” said Eric MacDonald, executive VP, Aecon Utilities.

“Aecon, together with Dufferin Concrete, are demonstrating that low carbon concrete additives are a key lever to help achieve 2050 net-zero goals,” said Natalie Giglio, senior business development associate, Carbon Upcycling. “This technology was developed to help build the circular carbon economy, and it’s great to see that it is supported by the industry on pilot projects like this and will be used by partners like Aecon to achieve their sustainability goals.”

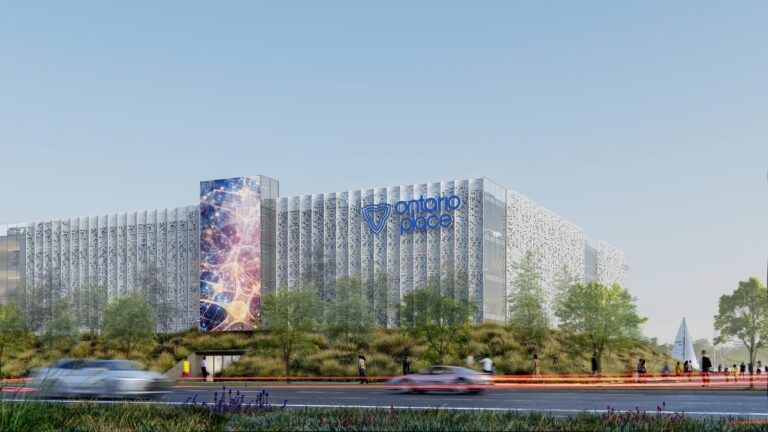

Featured image: (Twitter@AeconGroupInc)